The Role of Bridges in Watch Movements: Function and Aesthetics

Understanding the intricate workings of a mechanical watch movement is a fascinating journey for any enthusiast. While the mainspring and escapement often steal the spotlight, a critical, often-overlooked component is the bridge. These seemingly simple pieces play a vital role in the movement’s function and contribute significantly to its overall appearance. This article will delve into the function and aesthetics of watch movement bridges, explaining their purpose, different types, and how they're vital for both watch repair and the enjoyment of watch collecting. It's a cornerstone element in understanding the heart of mechanical timepieces.

What are Watch Movement Bridges?

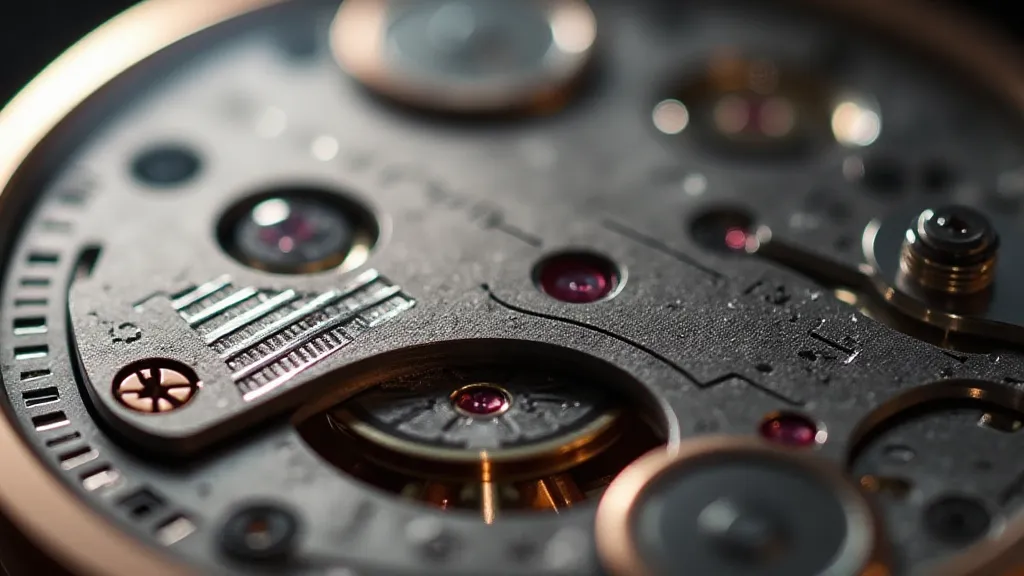

At its most basic, a bridge in a watch movement is a precisely machined plate that serves as a support for the gear train. The gear train comprises the wheels that transmit power from the mainspring to the escapement, ultimately driving the hands. Without bridges, these gears would simply spin freely, rendering the movement useless. Think of them as the foundation upon which the entire timekeeping process is built. The complexity of these movements, and the different philosophies behind their construction, can vary significantly. For those interested in tracing the lineage and identifying specific designs, exploring resources like an overview of Moya/Tissot movements can be a fascinating starting point.

The Functional Importance of Bridges

The role of bridges extends far beyond just simple support. Their functional importance is manifold:

- Gear Support: The primary function is to firmly hold the gear wheels in their correct positions. Each bridge is positioned to precisely align the gear teeth, ensuring smooth and efficient power transfer.

- Jewel Sinks: Bridges are typically drilled to accommodate jewel bearings (usually synthetic rubies or sapphires). These jewels are positioned at critical points in the gear train to reduce friction and wear. The bridges effectively create "sinks" for these jewels, securing them in place. Understanding the markings and codes used to identify these movements can add another layer of appreciation - a Swiss watch movement identifier can be a helpful tool for further investigation.

- Stability and Vibration Dampening: The rigidity of the bridges contributes to the overall stability of the movement. They help damp vibrations, contributing to the accuracy and reliability of the timepiece. A movement with loose or poorly fitted bridges will be less accurate.

- Protection of Delicate Components: Bridges act as a shield, protecting the delicate components of the gear train from dust, debris, and accidental damage.

- Movement Adjustment: Some bridges are designed with adjustable features, allowing for fine-tuning of the movement's performance. This is particularly common in high-end movements, where extreme accuracy is paramount.

Types of Bridges

Watch movement bridges aren’t all created equal. They vary in design and construction, reflecting different manufacturing philosophies and aesthetic choices. Here are some common types:

- Main Plate Bridges: These are larger bridges that span a significant portion of the main plate. They typically support key components like the barrel bridge and the third wheel bridge.

- Barrel Bridge: Specifically supports the mainspring barrel, a critical element for power delivery.

- Third Wheel Bridge: Supports the third wheel, a vital gear in the gear train, often a focal point for aesthetic finishing.

- Fourth Wheel Bridge: Supports the fourth wheel, often paired with the escape wheel bridge, contributing to the overall layout of the movement.

- Pallet Fork Bridge: Secures the pallet fork, which interacts with the escape wheel and regulates the release of power.

- Overbridges (or Auxiliary Bridges): These are bridges that sit *over* other bridges, providing additional support and often contributing to a more complex and visually appealing layout. They're commonly found in higher-grade movements.

Aesthetic Considerations: Finishing and Decoration

While functionality is paramount, the aesthetic appeal of bridges is equally important, particularly in high-end watches. Watchmakers often spend considerable time and effort decorating these components, transforming them from mere functional parts into works of art. Common finishing techniques include:

- Polishing (Anglage): This involves meticulously polishing the corners and edges of the bridges to create a rounded, beveled appearance. Anglage is a hallmark of fine watchmaking and adds a touch of elegance and sophistication.

- Geneva Stripes (Côtes de Genève): A distinctive striped pattern applied to the surface of the bridges using a specialized tool. It’s visually appealing and helps to reduce friction by providing a larger surface area for oil to spread.

- Circular Graining (Perlage): A swirling pattern applied to the surface of the bridges, creating a soft, reflective appearance.

- Brushing: A more utilitarian finishing technique that provides a matte finish.

- Black Polishing: A complex and time-consuming polishing technique that results in an incredibly deep, black-like polish, minimizing light reflection.

Bridges and Watch Repair

Understanding the role of bridges is crucial for anyone involved in watch repair. When disassembling a watch movement, the bridges are typically removed sequentially, and their precise positioning must be carefully noted. Here's why bridge knowledge is important for repair:

- Accurate Reassembly: Correct placement is vital for proper gear alignment and functionality.

- Identifying Wear and Damage: Bridges can reveal clues about the movement's history and potential problems. Wear patterns or cracks in the bridges can indicate excessive stress or poor lubrication.

- Troubleshooting: If a watch is running erratically, a loose or damaged bridge could be the culprit.

- Replacing Bridges: While less common, it is sometimes necessary to replace a damaged bridge. Finding a replacement that is an exact match can be challenging.

The choice between a manually wound movement and an automatic variant fundamentally impacts the complexity of the construction and the arrangement of components. Some may prefer the simplicity and traditional feel of a manual-wind, while others appreciate the convenience of an automatic. Understanding these differences is key to appreciating the nuances of horological design; a comparison of automatic vs. manual-wind movements can be quite illuminating.

The Evolution of Bridge Design

Watch movement bridge design has evolved over time, reflecting advancements in manufacturing technology and changes in aesthetic preferences. Early movements often featured simpler bridge designs, with fewer overbridges. As manufacturing techniques improved, watchmakers were able to create more complex and aesthetically pleasing bridge layouts. Modern high-end movements often feature intricate bridge arrangements that showcase the watchmaker's skill and artistry. Looking ahead, the industry is continually seeking innovations to enhance accuracy, efficiency, and aesthetics. Understanding the potential future directions of these movements – including new materials and construction techniques – provides a glimpse into the ongoing evolution of horology; a look at the future of watch movements might spark your interest.

Conclusion

The bridges in a watch movement are far more than just simple supports. They're essential components that contribute significantly to the movement's functionality, stability, and aesthetic appeal. Whether you're a seasoned watch repairer, a dedicated collector, or simply someone who appreciates the craftsmanship of mechanical timepieces, understanding the role of bridges can deepen your appreciation for the intricate world of watchmaking. Next time you admire a beautiful watch movement, take a moment to appreciate the artistry and engineering that went into the design and finishing of its bridges - those often-overlooked pillars of horological excellence.